Singapore will officially transition from the 4th revised edition of the UN GHS to the 7th Revised Edition on February 6, 2025.

Authorities announced revisions to the "Singapore Standards on Hazard Communication for Hazardous Chemicals and Dangerous Goods," SS 586-2: 2022 and SS 586-3: 2022 revisions, on February 6, 2023. They provided a two-year transition period. SS 586-2 pertains to the implementation of GHS classification and labeling in Singapore, while SS 586-3 sets out some requirements for the preparation of SDSs.

I. Adjustments in Hazard Classification

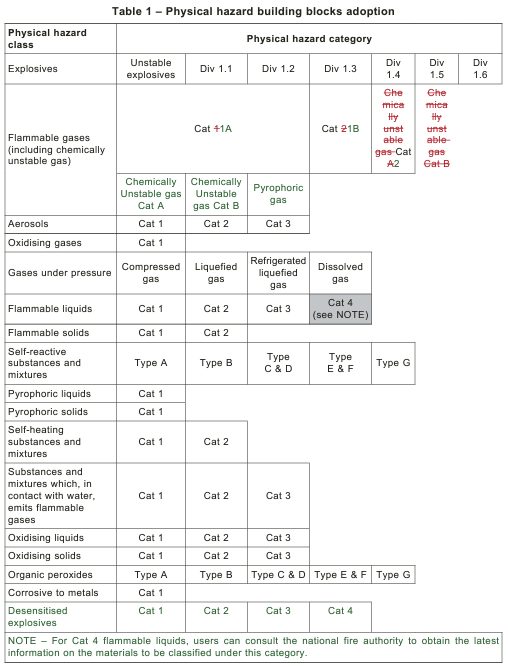

In the 2022 revision, the physical hazard category for flammable gases has been expanded to include a new subclass called "pyrophoric gas," and Category 1 for flammable gases has been further subdivided into Categories 1A and 1B.

Category 4 for flammable liquids has not been adopted, but users can consult the National Fire Department to obtain the latest information about materials that fall into this category.

A new classification for desensitized explosives has been introduced, comprised of four categories. According to the regulations, desensitized explosives are solid or liquid explosive substances or mixtures that have been desensitized to suppress their explosive properties so that they do not undergo a mass explosion and do not burn too quickly, thus exempting them from the "explosives" hazard category. There are no significant changes in health hazards and environmental hazards in the latest revision.

II. Adjustments in Generic Cut-off Values

Generic cut-off values are crucial references for determining the hazardous characteristics of chemicals. The cut-off value for acute toxicity no longer distinguishes between Categories 1-3 and Category 4, and is uniformly set at 1%.

For hazards to the aquatic environment, both acute and chronic, the generic cut-off value was previously undifferentiated by hazard category, but now 1% is specifically for Category 1.

A new generic cut-off value of 1% has been introduced for inhalation hazard Category 1.

Table 1: Generic Cut-off Values

| Hazard Classification | Generic Cut-off Value Considered |

| Acute Toxicity | 1% |

| Skin Corrosion/Irritation | 1% |

| Serious Eye Damage/Eye Irritation | 1% |

| Hazard to Aquatic Environment (Acute/Chronic), Category 1 | 1% |

| Inhalation Hazard, Category 1 | 1% |

III. Adjustment of SDS Cut-off Limit

The SDS Cut-off Limit is used to determine whether a substance/component needs to be disclosed in Section 3 of the SDS. The new revision involves adjustments to the Cut-off Limit for two hazard categories only.

The Cut-off Values for all acute toxicity categories have been adjusted to ≥1.0%, aligning the Cut-off Values for categories 1-3 with category 4. Thus, the requirements of the Cut-off Limit for acute toxicity categories 1-3 have been relaxed.

The Cut-off Value for inhalation hazard category 1 has been lowered to ≥1.0%, which is stricter than the previous 10%.

Table 2: SDS Cut-off Limit

| Hazard Category | Cut-off Value |

| Acute Toxicity | ≥ 1.0% |

| Skin Corrosion/Irritation | ≥ 1.0% |

| Eye Damage/Eye Irritation | ≥ 1.0% |

| Respiratory Sensitization | ≥ 0.1% |

| Skin Sensitization | ≥ 0.1% |

| Germ Cell Mutagenicity (Category 1) | ≥ 0.1% |

| Germ Cell Mutagenicity (Category 2) | ≥ 1.0% |

| Carcinogenicity | ≥ 0.1% |

| Reproductive Toxicity | ≥ 0.1% |

| Specific Target Organ Toxicity - Single Exposure | ≥ 1.0% |

| Specific Target Organ Toxicity - Repeated Exposure | ≥ 1.0% |

| Hazardous to the Aquatic Environment | ≥ 1.0% |

| Hazardous to the Ozone Layer | ≥ 0.1% |

| Inhalation Hazard, Category 1 | ≥ 1.0% |

IV. Key Updates to SDS Content

For other hazards that do not lead to GHS classification, it is necessary to explain these in Section 2 of the SDS. For substances or mixtures with dust explosion hazards, it should be stated in Section 2 of the SDS: "May form explosive dust-air mixtures if dispersed."

If the chemical is a nanomaterial, this must be specified in Section 3.

Section 7 should include safe handling and storage methods for substances or mixtures with combustible dust hazards.

In Section 9, kinematic viscosity and particle characteristics have been added. Additionally, the updated regulations allow for the use of "masked names" under specific conditions to protect Confidential Business Information (CBI).

Appendices D and E from the 7th revised edition of UN GHS have been added to explain basic physical, and chemical properties, and safety characteristics.

V. Key Updates to Label Content

Similar to SDS, if a chemical product poses a combustible dust explosion hazard, the label should state "Warning: May form explosive dust-air mixtures if dispersed."

For chemical waste handled for the purpose of recycling or resale, a complete label should be prepared in accordance with SS 586-2.

The new Annex B provides examples of labels for small packages of solvents ≤125mL. Labels on small packages must at least include product identification and pictograms, while the outer packaging should display the complete GHS label. For small intermediate containers that cannot be labeled due to their shape, size, or the method of use, they must be placed on outer packaging that can display the full GHS label.

Figure 2: Examples of Labels for Small Container Packaging

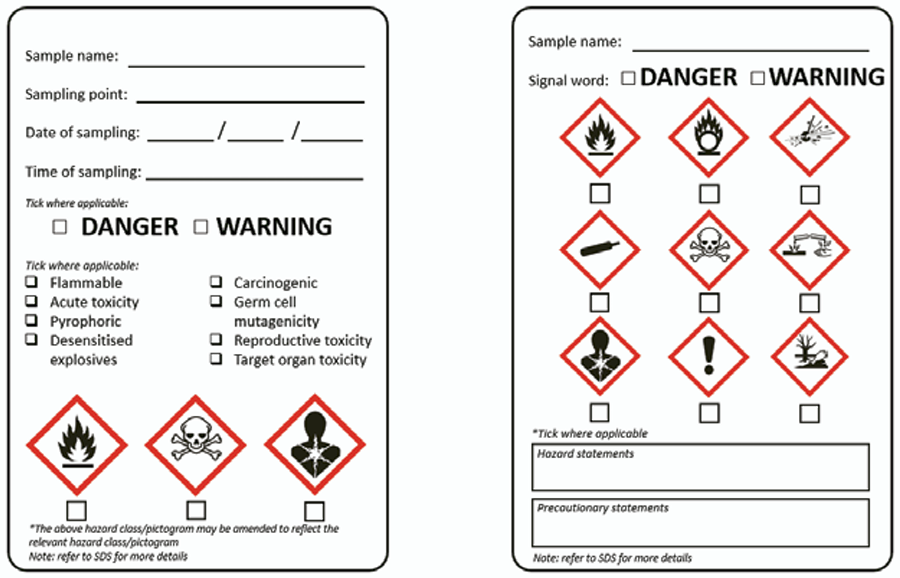

For labels on samples collected from process lines in a factory, a simplified workplace label should be used on the sample containers during storage. This is to alert personnel who may come into contact with the hazardous chemical on its potential hazards.

Figure 3: Example of a Label for In-Process Samples

VI. Updates and Review of Label and SDS Information

Once new information is received, suppliers and workplace personnel are required to update the SDS and labels within six months.

For editorial changes to the SDS and/or labels that do not affect the transportation, storage, handling, and licensing of the chemicals (such as changes to titles or subtitles), updates should be made within 12 months.

Chemical suppliers must review the information used to support the preparation of SDSs and labels every five years. This review is mandatory even if no new significant information has been obtained. Suppliers need to maintain records of these reviews to ensure compliance and traceability.

If you need any assistance or have any questions, please get in touch with us via service@cirs-group.com.

Further Information